Vicenza: paving a sloping garage slide

In this project, we renovated the access slide to the garage: the material chosen was porphyry, arranged in cubes and decorated with cobblestones.

Discover the realisation:

Ramp

In single-family homes and apartment buildings with underground garages, the design of the driveway ramp is a crucial phase that impacts both functionality and safety. To ensure comfort, durability, and compliance with regulations, it is essential to carefully define slopes, curvature radii, clearance heights, and surface materials. Let’s explore each of these elements in detail.

1. Recommended Slopes and Regulatory Limits

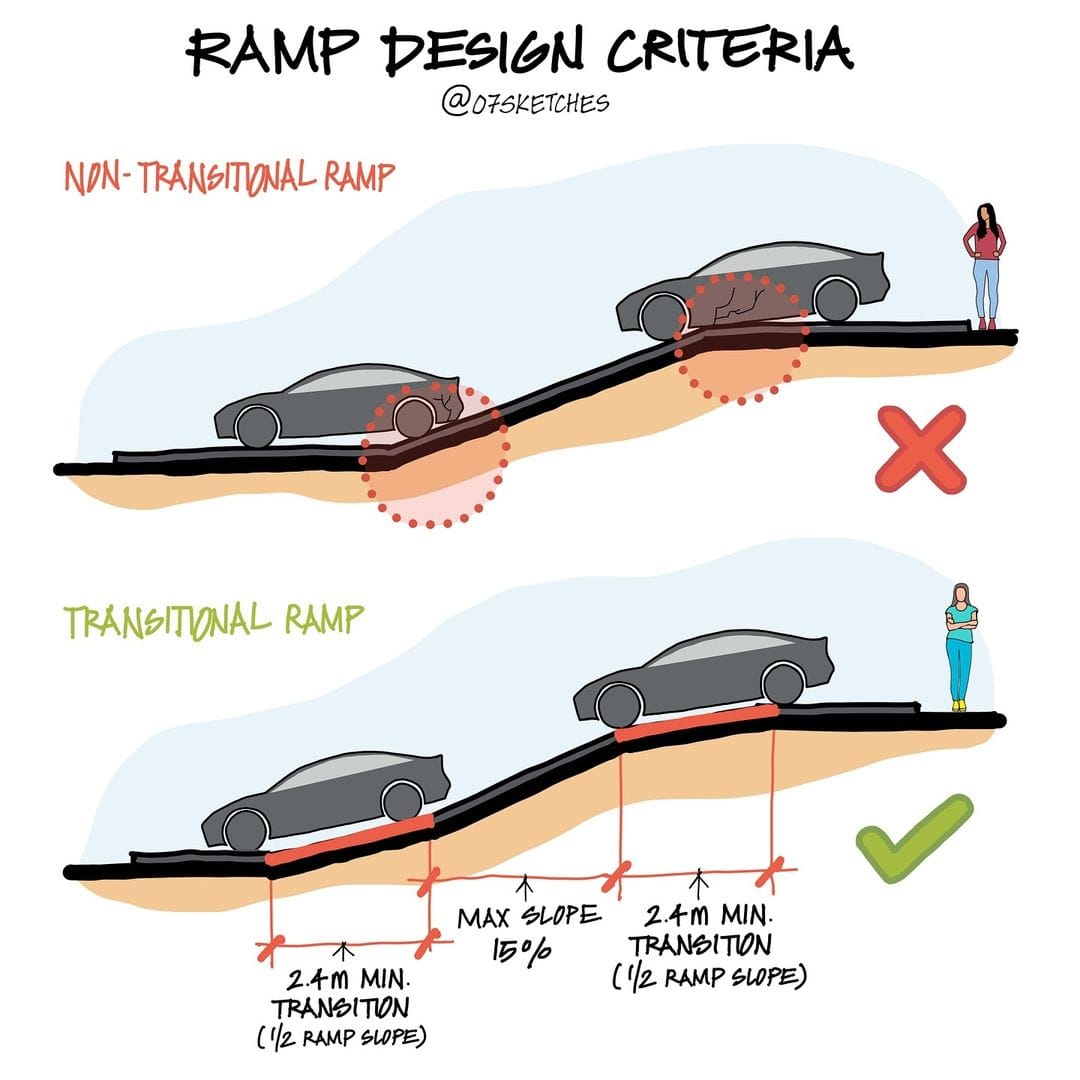

The slope of the ramp is the first key parameter, as it directly affects both accessibility and safety. In general:

- Maximum recommended slope:

- 18% for private residential access

- 15% for shared residential garages

- 8–10% for public-use garages (e.g., commercial)

- Horizontal transition zones:

To avoid vehicle undercarriage scraping, it’s advisable to include flat entry and exit zones measuring 1.5–2.0 meters. - Cross slope:

A slight cross slope of 1–2% should be provided to allow rainwater runoff.

2. Straight or Curved Ramp? Minimum Turning Radius

A straight ramp is not always feasible. When planimetric constraints are present, a curved ramp may be required. In such cases, it’s crucial to respect the minimum internal turning radius, which should match the turning capabilities of standard vehicles:

- Recommended minimum radius:

- 5.0 m for mid-sized vehicles

- 6.0 m for greater maneuverability

- In compact spaces, 4.5 m can work with small cars

This radius should be tested using a CAD simulation and a standard vehicle envelope (DIN 70020 or ISO 612 models).

3. Clearance Heights and Vertical Requirements

To accommodate SUVs and high-roof vehicles, the ramp must maintain sufficient vertical clearance throughout the path:

- Minimum vertical clearance:

- 2.20 m near beams or overhangs

- 2.40 m is recommended for optimal comfort and accessibility

This height must be measured along the vehicle trajectory, accounting for slope variations and turning angles.

4. Suitable Ramp Surfacing Materials

Choosing the right surface is essential to ensure grip, durability, and ease of maintenance. Commonly used materials include:

- Brushed or troweled concrete with transverse grooves:

A cost-effective solution with excellent traction even in wet conditions. - Architectural concrete or stamped concrete:

A more decorative choice, though anti-slip finishes must be applied. - Porphyry or natural stone cobbles:

Very durable, but require skilled installation and periodic maintenance. - Permeable surfaces (e.g., porous concrete or GravelFix grids):

Ideal for water drainage but must be combined with proper slope and drainage systems. - Anti-slip porcelain stoneware:

Rarely used for driveways due to jointing and impact risk, but viable for light vehicle use.

5. Technical Details and Drainage Considerations

A properly designed ramp must prevent rainwater from entering the basement. Key solutions include:

- Grated trench drain:

Placed just before the garage entrance to collect and channel water into the drainage system. - Side curbs and waterproofing:

To prevent water infiltration into retaining walls. - Lighting and signage:

Adequate lighting should be provided, ideally with motion or dusk sensors. - Anti-ice measures:

In cold climates, consider electric heating cables or anti-slip surface treatments.

6. Integrating the Ramp with the Architectural Project

A ramp is not merely a technical element—it must be integrated into the overall design of the building and landscape. It can be:

- Hidden with landscaping or retaining walls

- Clad in façade or exterior paving materials

- Highlighted as a design feature with lighting and stone finishes

Conclusion

Designing a driveway ramp should never be improvised. A well-thought-out approach ensures ease of access, safety, long-term durability, and aesthetic harmony with the building. Collaborating with skilled designers, engineers, and contractors is key to achieving a functional and visually pleasing result.